| |

| Identifiers | |

|---|---|

3D model (JSmol)

|

|

| ChemSpider |

|

| |

| Properties | |

| (C6H6O·CH2O)n | |

| Molar mass | Variable |

| Appearance | Brown solid |

| Density | 1.3 g/cm3[1] |

| Thermal conductivity | 0.2 W/(m·K)[1] |

Refractive index (nD)

|

1.63[2] |

| Thermochemistry | |

Heat capacity (C)

|

0.92 kJ/(kg·K)[1] |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

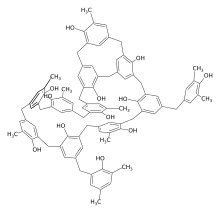

Bakelite (/ˈbeɪkəlaɪt/ BAY-kə-lyte), formally polyoxybenzylmethyleneglycolanhydride, is a thermosetting phenol formaldehyde resin, formed from a condensation reaction of phenol with formaldehyde. The first plastic made from synthetic components, it was developed by Leo Baekeland in Yonkers, New York, in 1907, and patented on December 7, 1909.[3]

Bakelite was one of the first plastic-like materials to be introduced into the modern world and was popular because it could be moulded and then hardened into any shape.

Because of its electrical nonconductivity and heat-resistant properties, it became a great commercial success. It was used in electrical insulators, radio and telephone casings, and such diverse products as kitchenware, jewelry, pipe stems, children's toys, and firearms.

The retro appeal of old Bakelite products has made them collectible.[4]

The creation of a synthetic plastic was revolutionary for the chemical industry, which at the time made most of its income from cloth dyes and explosives. Bakelite's commercial success inspired the industry to develop other synthetic plastics. As the world's first commercial synthetic plastic, Bakelite was named a National Historic Chemical Landmark by the American Chemical Society.[5]

- ^ a b c Laughton M A; Say M G (2013). Electrical Engineer's Reference Book. Elsevier. p. 1.21. ISBN 978-1-4831-0263-4.

- ^ Tickell, F. G. (2011). The techniques of sedimentary mineralogy. Elsevier. p. 57. ISBN 978-0-08-086914-8.

- ^ U.S. patent 942699A

- ^ Cook, Patrick; Slessor, Catherine (1998). An illustrated guide to bakelite collectables. London: Quantum. ISBN 9781861602121.

- ^ American Chemical Society National Historic Chemical Landmarks. "Bakelite: The World's First Synthetic Plastic". Retrieved February 23, 2015.