This article needs additional citations for verification. (October 2010) |

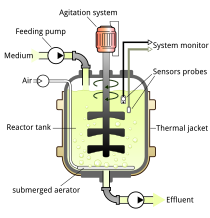

A bioreactor is any manufactured device or system that supports a biologically active environment.[1] In one case, a bioreactor is a vessel in which a chemical process is carried out which involves organisms or biochemically active substances derived from such organisms. This process can either be aerobic or anaerobic. These bioreactors are commonly cylindrical, ranging in size from litres to cubic metres, and are often made of stainless steel.[citation needed] It may also refer to a device or system designed to grow cells or tissues in the context of cell culture.[2] These devices are being developed for use in tissue engineering or biochemical/bioprocess engineering.[citation needed]

On the basis of mode of operation, a bioreactor may be classified as batch, fed batch or continuous (e.g. a continuous stirred-tank reactor model). An example of a continuous bioreactor is the chemostat.[citation needed]

Organisms or biochemically active substances growing in bioreactors may be submerged in liquid medium or may be anchored to the surface of a solid medium. Submerged cultures may be suspended or immobilized. Suspension bioreactors may support a wider variety of organisms, since special attachment surfaces are not needed, and can operate at a much larger scale than immobilized cultures. However, in a continuously operated process the organisms will be removed from the reactor with the effluent. Immobilization is a general term describing a wide variety of methods for cell or particle attachment or entrapment.[3] It can be applied to basically all types of biocatalysis including enzymes, cellular organelles, animal and plant cells and organs.[4][5] Immobilization is useful for continuously operated processes, since the organisms will not be removed with the reactor effluent, but is limited in scale because the microbes are only present on the surfaces of the vessel.

Large scale immobilized cell bioreactors are:

- moving media, also known as moving bed biofilm reactor (MBBR)

- packed bed

- fibrous bed

- membrane

- ^ IUPAC, Compendium of Chemical Terminology, 2nd ed. (the "Gold Book") (1997). Online corrected version: (2006–) "bioreactor". doi:10.1351/goldbook.B00662

- ^ "Bioreactoes and Cultivation Systems for Cell and Tissue Culture" (PDF). eolss.net. Retrieved 12 August 2023.

- ^ López, Asunción; Lázaro, Nuria; Marqués, Ana M. (September 1997). "The interphase technique: a simple method of cell immobilization in gel-beads". Journal of Microbiological Methods. 30 (3): 231–234. doi:10.1016/S0167-7012(97)00071-7.

- ^ Kowalczyk, Tomasz; Sitarek, Przemysław; Toma, Monika; Rijo, Patricia; Domínguez‐Martín, Eva; Falcó, Irene; Sánchez, Gloria; Śliwiński, Tomasz (August 2021). "Enhanced Accumulation of Betulinic Acid in Transgenic Hairy Roots of Senna obtusifolia Growing in the Sprinkle Bioreactor and Evaluation of Their Biological Properties in Various Biological Models". Chemistry & Biodiversity. 18 (8): e2100455. doi:10.1002/cbdv.202100455. hdl:10261/247635. ISSN 1612-1872. PMID 34185351. S2CID 235672736.

- ^ Peinado, Rafael A.; Moreno, Juan J.; Villalba, Jose M.; González-Reyes, Jose A.; Ortega, Jose M.; Mauricio, Juan C. (December 2006). "Yeast biocapsules: A new immobilization method and their applications". Enzyme and Microbial Technology. 40 (1): 79–84. doi:10.1016/j.enzmictec.2005.10.040.