This article needs additional citations for verification. (July 2023) |

Sabrina I is a modern Handymax bulk carrier.

| |

| Class overview | |

|---|---|

| Subclasses | Handymax, Handysize, Panamax, Capesize, Chinamax |

| Built | c. 1850–present |

| Active | 12,700 vessels over 500 GT (2021)[1] |

| General characteristics (typical) | |

| Type | Bulk carrier |

| Tonnage | up to 400,000 DWT |

| Length | 300 m (980 ft) |

| Height | 40 m (130 ft) |

| Propulsion | 2-stroke diesel engine and 1 propeller |

| Speed | 12 knots |

| Notes | Rear house, full hull, series of large hatches |

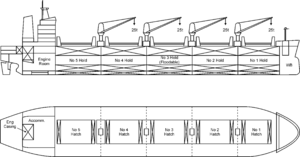

Plans of a geared Handymax bulk carrier

| |

A bulk carrier or bulker is a merchant ship specially designed to transport unpackaged bulk cargo—such as grain, coal, ore, steel coils, and cement—in its cargo holds. Since the first specialized bulk carrier was built in 1852, economic forces have led to increased size and sophistication of these ships. Today's bulk carriers are specially designed to maximize capacity, safety, efficiency, and durability.

Today, bulk carriers make up 21 percent of the world's merchant fleets,[2] and they range in size from single-hold mini-bulk carriers to mammoth ore ships able to carry 400,000 metric tons of deadweight (DWT). A number of specialized designs exist: some can unload their own cargo, some depend on port facilities for unloading, and some even package the cargo as it is loaded. Over half of all bulk carriers have Greek, Japanese, or Chinese owners, and more than a quarter are registered in Panama. South Korea is the largest single builder of bulk carriers, and 82 percent of these ships were built in Asia.

On bulk carriers, crews are involved in operation, management, and maintenance of the vessel, taking care of safety, navigation, maintenance, and cargo care, in accordance with international maritime legislation. Crews can range in size from three people on the smallest ships to over 30 on the largest.

Cargo loading operations vary in complexity, and loading and discharging of cargo can take several days. Bulk carriers can be gearless (dependent upon terminal equipment) or geared (having cranes integral to the vessel).

Bulk cargo can be very dense, corrosive, or abrasive. This can present safety problems that can threaten a ship: problems such as cargo shifting, spontaneous combustion, and cargo saturation. The use of old ships that have corrosion problems—as well as the bulk carriers' large hatchways—have been linked to a spate of bulk carrier sinkings in the 1990s. These large hatchways, important for efficient cargo handling, can allow the entry of large volumes of water in storms and accelerate sinking once a vessel has listed or heeled. New international regulations have since been introduced to improve ship design and inspection and to streamline the process for crews to abandon ship.

- ^ Dry Bulk Market Primer

- ^ "• Global merchant fleet - number of ships by type 2019 | Statista". 22 December 2019. Archived from the original on 22 December 2019. Retrieved 29 March 2021.