This article needs additional citations for verification. (December 2015) |

| |

| Names | |

|---|---|

| Other names

Poly(ethylene-vinyl acetate); poly(ethylene-co-vinyl acetate); polyethylene-vinyl acetate copolymer

| |

| Identifiers | |

| Abbreviations | EVA; PEVA |

| ChEBI | |

| ChemSpider |

|

| ECHA InfoCard | 100.133.085 |

PubChem CID

|

|

| UNII | |

CompTox Dashboard (EPA)

|

|

| Properties | |

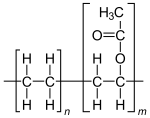

| (C2H4)n(C4H6O2)m | |

| Molar mass | Variable |

| Melting point | 90 °C (194 °F) |

| Hazards | |

| Safety data sheet (SDS) | MSDS |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

Ethylene-vinyl acetate (EVA), also known as poly(ethylene-vinyl acetate) (PEVA), is a copolymer of ethylene and vinyl acetate. The weight percent of vinyl acetate usually varies from 10 to 50%, with the remainder being ethylene. There are three different types of EVA copolymer, which differ in the vinyl acetate (VA) content and the way the materials are used.

The EVA copolymer which is based on a low proportion of VA (approximately up to 4%) may be referred to as vinyl acetate modified polyethylene. It is a copolymer and is processed as a thermoplastic material – just like low-density polyethylene. It has some of the properties of a low-density polyethylene but increased gloss (useful for film), softness and flexibility. The material is generally considered non-toxic.

The EVA copolymer which is based on a medium proportion of VA (approximately 4 to 30%) is referred to as thermoplastic ethylene-vinyl acetate copolymer and is a thermoplastic elastomer material. It is not vulcanized but has some of the properties of a rubber or of plasticized polyvinyl chloride particularly at the higher end of the range. Both filled and unfilled EVA materials have good low temperature properties and are tough. The materials with approximately 11% VA are used as hot-melt adhesives.

The EVA copolymer which is based on a high proportion of VA (greater than 60%) is referred to as ethylene-vinyl acetate rubber.[1]

EVA is an elastomeric polymer that produces materials which are "rubber-like" in softness and flexibility. The material has good clarity and gloss, low-temperature toughness, stress-crack resistance, hot-melt adhesive waterproof properties, and resistance to UV radiation. EVA has a distinctive vinegar-like odor and is competitive with rubber and vinyl polymer products in many electrical applications.

- ^ Whelan, A.; Whelan, Tony (27 May 1994). Polymer Technology Dictionary. Springer Science & Business Media. ISBN 9780412581809 – via Google Books.