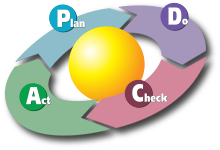

PDCA or plan–do–check–act (sometimes called plan–do–check–adjust) is an iterative design and management method used in business for the control and continual improvement of processes and products.[1] It is also known as the Shewhart cycle, or the control circle/cycle. Another version of this PDCA cycle is OPDCA.[2] The added "O" stands for observation or as some versions say: "Observe the current condition." This emphasis on observation and current condition has currency with the literature on lean manufacturing and the Toyota Production System.[3] The PDCA cycle, with Ishikawa's changes, can be traced back to S. Mizuno of the Tokyo Institute of Technology in 1959.[4]

The PDCA cycle is also known as PDSA cycle (where S stands for study). It was an early means of representing the task areas of traditional quality management. The cycle is sometimes referred to as the Shewhart / Deming cycle since it originated with physicist Walter Shewhart at the Bell Telephone Laboratories in the 1920s. W. Edwards Deming modified the Shewhart cycle in the 1940s and subsequently applied it to management practices in Japan in the 1950s.[5]

Deming found that the focus on Check is more about the implementation of a change, with success or failure. His focus was on predicting the results of an improvement effort, Study of the actual results, and comparing them to possibly revise the theory.

- ^ Tague, Nancy R. (2005) [1995]. "Plan–Do–Study–Act cycle". The quality toolbox (2nd ed.). Milwaukee: ASQ Quality Press. pp. 390–392. ISBN 978-0873896399. OCLC 57251077.

- ^ Foresight University, The Foresight Guide, Shewhart's Learning and Deming's Quality Cycle, [1]

- ^ Rother, Mike (2010). Toyota kata: managing people for improvement, adaptiveness, and superior results. New York: McGraw-Hill. ISBN 978-0071635233. OCLC 318409119.

- ^ Cite error: The named reference

:0was invoked but never defined (see the help page). - ^ "18.2.1 The Deming Cycle (PDCA Cycle) and the Shewhart Cycle". Retrieved 2023-04-17.