Rolling Contact Fatigue (RCF) is a phenomenon that occurs in mechanical components relating to rolling/sliding contact, such as railways, gears, and bearings.[2] It is the result of the process of fatigue due to rolling/sliding contact.[2][3] The RCF process begins with cyclic loading of the material, which results in fatigue damage that can be observed in crack-like flaws, like white etching cracks.[2] These flaws can grow into larger cracks under further loading, potentially leading to fractures.[2][4]

In railways, for example, when the train wheel rolls on the rail, creating a small contact patch that leads to very high contact pressure between the rail and wheel.[2] Over time, the repeated passing of wheels with high contact pressures can cause the formation of crack-like flaws that becomes small cracks.[2] These cracks can grow and sometimes join, leading to either surface spalling or rail break, which can cause serious accidents, including derailments.[2][4]

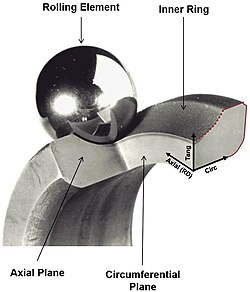

RCF is a major concern for railways worldwide and can take various forms depending on the location of the crack and its appearance.[2] It is also a significant cause of failure in components subjected to rolling or rolling/sliding contacts, such as rolling-contact bearings, gears, and cam/tappet arrangements.[5] The alternating stress field in RCF can lead to material removal, varying from micro- and macro-pitting in conventional bearing steels to delamination in hybrid ceramics and overlay coatings.[5]

- ^ Curd, M. E.; Burnett, T. L.; Fellowes, J.; Donoghue, J.; Yan, P.; Withers, P. J. (2019-08-01). "The heterogenous distribution of white etching matter (WEM) around subsurface cracks in bearing steels". Acta Materialia. 174: 300–309. Bibcode:2019AcMat.174..300C. doi:10.1016/j.actamat.2019.05.052. ISSN 1359-6454.

- ^ a b c d e f g h Kapoor, Ajay; Salehi, Iman; Asih, Anna Maria Sri (2013), "Rolling Contact Fatigue (RCF)", in Wang, Q. Jane; Chung, Yip-Wah (eds.), Encyclopedia of Tribology, Boston, MA: Springer US, pp. 2904–2910, doi:10.1007/978-0-387-92897-5_287, ISBN 978-0-387-92897-5, retrieved 2024-03-14

- ^ "Rolling Contact Fatigue – About Tribology". Retrieved 2024-03-14.

- ^ a b Kang, Young Sup (2013), "Rolling Bearing Contact Fatigue", in Wang, Q. Jane; Chung, Yip-Wah (eds.), Encyclopedia of Tribology, Boston, MA: Springer US, pp. 2820–2824, doi:10.1007/978-0-387-92897-5_375, ISBN 978-0-387-92897-5, retrieved 2024-03-14

- ^ a b Ahmed, R. "Rolling Contact Fatigue" (PDF). Heriot-Watt University.