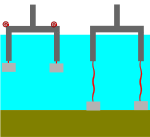

A tension-leg platform (TLP) or extended tension leg platform (ETLP) is a vertically moored floating structure normally used for the offshore production of oil or gas, and is particularly suited for water depths greater than 300 metres (about 1000 ft) and less than 1500 metres (about 4900 ft). Use of tension-leg platforms has also been proposed for offshore wind turbines.

The platform is permanently moored by means of tethers or tendons grouped at each of the structure's corners. A group of tethers is called a tension leg. A feature of the design of the tethers is that they have relatively high axial stiffness (low elasticity), such that virtually all vertical motion of the platform is eliminated. This allows the platform to have the production wellheads on deck (connected directly to the subsea wells by rigid risers), instead of on the seafloor. This allows a simpler well completion and gives better control over the production from the oil or gas reservoir, and easier access for downhole intervention operations.

TLPs have been in use since the early 1980s. The first tension leg platform[1] was built for Conoco's Hutton field in the North Sea in the early 1980s. The hull was built in the dry-dock at Highland Fabricator's Nigg yard in the north of Scotland, with the deck section built nearby at McDermott's yard at Ardersier. The two parts were mated in the Moray Firth in 1984.

The Hutton TLP was originally designed for a service life of 25 years in North Sea depth of 100 to 1000 metres. It had 16 tension legs. Its weight varied between 46,500 and 55,000 tons when moored to the seabed, but up to 61,580 tons when floating freely.[1] The total area of its living quarters was about 3,500 square metres and accommodated over 100 cabins though only 40 people were necessary to maintain the structure in place.[1]

The hull of the Hutton TLP has been separated from the topsides. Topsides have been redeployed to the Prirazlomnoye field in the Barents Sea, while the hull was reportedly sold to a project in the Gulf of Mexico (although the hull has been moored in Cromarty Firth since 2009).[2]

Larger TLPs will normally have a full drilling rig on the platform with which to drill and intervene on the wells. The smaller TLPs may have a workover rig, or with most recent TLPs, production wellheads located at remote drillcentres subsea.

The deepest (E)TLPs measured from the sea floor to the surface are:[3]

- 5,185 ft (1,580 m) Big Foot ETLP

- 4,674 ft (1,425 m) Magnolia ETLP. Its total height is some 5,000 feet (1,500 m).

- 4,300 ft (1,300 m) Marco Polo TLP

- 4,250 ft (1,300 m) Neptune TLP

- 3,863 ft (1,177 m) Kizomba A TLP

- 3,800 ft (1,200 m) Ursa TLP. Its height above surface is 485 ft (148 m) making a total height of 4,285 ft (1,306 m).[4]

- 3,350 ft (1,020 m) Allegheny TLP

- 3,300 ft (1,000 m) W. Seno A TLP