This article needs additional citations for verification. (May 2020) |

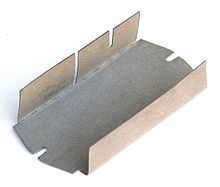

Vulcanized fibre also known as red fibre is a laminated plastic composed of only cellulose. This material is a tough, resilient, hornlike material that is lighter than aluminium, tougher than leather, and stiffer than most thermoplastics. The newer wood-laminating grade of vulcanized fibre is used to strengthen wood laminations used in skis, skateboards, support beams and as a sub-laminate under thin wood veneers. It could also be Blue. A product very similar to vulcanized fibre is leatheroid; however, Leatheroid is made using a different chemical process. Since 2004, the scientific community has regained interest in this material due to its renewability and excellent physical properties, giving birth to the field of all-cellulose composites.[1] These composites are all made of a matrix consisting of dissolved or partially dissolved cellulose, and the reinforcement remains cellulose fibres. A variety of solvents other than zinc chloride has been explored, including sodium hydroxide at low temperatures and ionic liquids.[2][3] Whereas the original idea was to use long reinforcing fibres (ramie, flax, viscose, etc) in order to confer the composites with anisotropic mechanical properties, the field has also explored the use of nanocellulose.

- ^ Huber, Tim; Müssig, Jorg; Curnow, Owen; Pang, Shusheng; Bickerton, Simon; Staiger, Mark (2012). "A critical review of all-cellulose composites". Journal of Materials Science. 47 (3): 1171–1186. Bibcode:2012JMatS..47.1171H. doi:10.1007/s10853-011-5774-3.

- ^ Duchemin, Benoit; Mathew, Aji; Oksman, Kristiina (2009). "All-cellulose composites by partial dissolution in the ionic liquid 1-butyl-3-methylimidazolium chloride". Composites Part A: Applied Science and Manufacturing. 40 (12): 1171–1186. doi:10.1016/j.compositesa.2009.09.013.

- ^ Dormanns, Jan; Schuermann, Jeremias; Müssig, Jorg; Duchemin, Benoit; Staiger, Mark (2016). "Solvent infusion processing of all-cellulose composite laminates using an aqueous NaOH/urea solvent system". Composites Part A: Applied Science and Manufacturing. 82: 130–140. doi:10.1016/j.compositesa.2015.12.002.