This article includes a list of general references, but it lacks sufficient corresponding inline citations. (December 2013) |

| Control chart | |

|---|---|

| |

| One of the Seven basic tools of quality | |

| First described by | Walter A. Shewhart |

| Purpose | To determine whether a process should undergo a formal examination for quality-related problems |

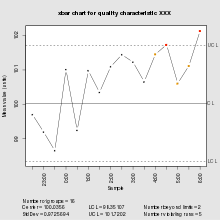

Control charts are graphical plots used in production control to determine whether quality and manufacturing processes are being controlled under stable conditions. (ISO 7870-1)[1] The hourly status is arranged on the graph, and the occurrence of abnormalities is judged based on the presence of data that differs from the conventional trend or deviates from the control limit line. Control charts are classified into Shewhart individuals control chart (ISO 7870-2)[2] and CUSUM(CUsUM)(or cumulative sum control chart)(ISO 7870-4).[3]

Control charts, also known as Shewhart charts (after Walter A. Shewhart) or process-behavior charts, are a statistical process control tool used to determine if a manufacturing or business process is in a state of control. It is more appropriate to say that the control charts are the graphical device for Statistical Process Monitoring (SPM). Traditional control charts are mostly designed to monitor process parameters when the underlying form of the process distributions are known. However, more advanced techniques are available in the 21st century where incoming data streaming can-be monitored even without any knowledge of the underlying process distributions. Distribution-free control charts are becoming increasingly popular[citation needed].

- ^ "Control charts — Part 1: General guidelines". iso.org. Retrieved 2022-12-11.

- ^ "Control charts — Part 2: Shewhart control charts". iso.org. Retrieved 2022-12-11.

- ^ "Control charts — Part 4: Cumulative sum charts". iso.org. Retrieved 2022-12-11.