This article needs additional citations for verification. (May 2023) |

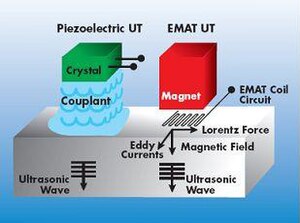

An electromagnetic acoustic transducer (EMAT) is a transducer for non-contact acoustic wave generation and reception in conducting materials. Its effect is based on electromagnetic mechanisms, which do not need direct coupling with the surface of the material. Due to this couplant-free feature, EMATs are particularly useful in harsh, i.e., hot, cold, clean, or dry environments. EMATs are suitable to generate all kinds of waves in metallic and/or magnetostrictive materials. Depending on the design and orientation of coils and magnets, shear horizontal (SH) bulk wave mode (norm-beam or angle-beam), surface wave, plate waves such as SH and Lamb waves, and all sorts of other bulk and guided-wave modes can be excited.[1][2][3] After decades of research and development, EMAT has found its applications in many industries such as primary metal manufacturing and processing, automotive, railroad, pipeline, boiler and pressure vessel industries,[3] in which they are typically used for nondestructive testing (NDT) of metallic structures.

- ^ R.B. Thompson, Physical Principles of Measurements with EMAT Transducers,Ultrasonic Measurement Methods, Physical Acoustics Vol XIX, Edited by R.N. Thurston and Allan D. Pierce, Academic Press, 1990

- ^ B.W. Maxfield, A. Kuramoto, and J.K. Hulbert, Evaluating EMAT Designs for Selected Applications, Mater. Eval., Vol 45, 1987, p1166

- ^ a b Innerspec Technologies