| |

| Names | |

|---|---|

| IUPAC name

Lead zirconium titanate

| |

| Other names

Lead zirconium titanate

| |

| Identifiers | |

3D model (JSmol)

|

|

| ECHA InfoCard | 100.032.467 |

| EC Number |

|

PubChem CID

|

|

CompTox Dashboard (EPA)

|

|

| |

| |

| Properties | |

| Pb[ZrxTi1−x]O3 (0 ≤ x ≤ 1) | |

| Molar mass | 303.065 to 346.4222 g/mol |

| Hazards | |

| GHS labelling: | |

| |

| Danger | |

| H302, H332, H360, H373, H410 | |

| P201, P202, P260, P261, P264, P270, P271, P273, P281, P301+P312, P304+P312, P304+P340, P308+P313, P312, P314, P330, P391, P405, P501 | |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

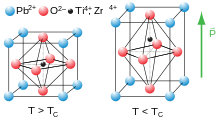

Lead zirconate titanate, also called lead zirconium titanate and commonly abbreviated as PZT, is an inorganic compound with the chemical formula Pb[ZrxTi1−x]O3 (0 ≤ x ≤ 1).. It is a ceramic perovskite material that shows a marked piezoelectric effect, meaning that the compound changes shape when an electric field is applied. It is used in a number of practical applications such as ultrasonic transducers and piezoelectric resonators. It is a white to off-white solid.[1]

Lead zirconium titanate was first developed around 1952 at the Tokyo Institute of Technology. Compared to barium titanate, a previously discovered metallic-oxide-based piezoelectric material, lead zirconium titanate exhibits greater sensitivity and has a higher operating temperature. Piezoelectric ceramics are chosen for applications because of their physical strength, chemical inertness and their relatively low manufacturing cost. PZT ceramic is the most commonly used piezoelectric ceramic because it has an even greater sensitivity and higher operating temperature than other piezoceramics.[2] Recently, there has been a large push towards finding alternatives to PZT due to legislations in many countries restricting the use of lead alloys and compounds in commercial products.

- ^ Gregg, J. Marty; Unruh, Hans-Günther (2016). "Ferroelectrics". Ullmann's Encyclopedia of Industrial Chemistry. pp. 1–26. doi:10.1002/14356007.a10_309.pub2. ISBN 978-3-527-30385-4.

- ^ "What is "Lead zirconium titanate"?". americanpiezo.com. APC International. Retrieved April 29, 2021.