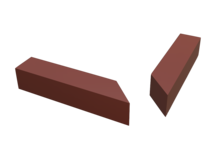

A miter joint (mitre in British English) is a joint made by cutting each of two parts to be joined, across the main surface, usually at a 45° angle, to form a corner, usually to form a 90° angle, though it can comprise any angle greater than 0 degrees. It is called beveling when the angled cut is done on the side, although the resulting joint is still a miter joint.[1]

For woodworking, a disadvantage of a miter joint is its weakness, but it can be strengthened with a spline (a thin wafer of wood inserted into a slot, usually arranged with the long grain of the spline across the short grain of the frame timber).[2] There are two common variations of a splined miter joint, one where the spline is long and runs the length of the mating surfaces and another where the spline is perpendicular to the joined edges.

Common applications include picture frames, pipes, and molding.

- ^ Oxford English Dictionary. Oxford University Press. 2009.

A usually right-angled joint in wood or other material in which the angle made by the joined pieces is bisected by the line or plane of junction; more fully mitre joint

- ^ "Splined Miter Joint". Woodworkingtips.com. Retrieved 2012-04-01.