This article includes a list of general references, but it lacks sufficient corresponding inline citations. (May 2012) |

Oxy-fuel welding torch (commonly called oxyacetylene welding, oxy welding, or gas welding in the United States) and oxy-fuel cutting are processes that use fuel gases (or liquid fuels such as gasoline or petrol, diesel, biodiesel, kerosene, etc) and oxygen to weld or cut metals. French engineers Edmond Fouché and Charles Picard became the first to develop oxygen-acetylene welding in 1903.[1] Pure oxygen, instead of air, is used to increase the flame temperature to allow localized melting of the workpiece material (e.g. steel) in a room environment.

A common propane/air flame burns at about 2,250 K (1,980 °C; 3,590 °F),[2] a propane/oxygen flame burns at about 2,526 K (2,253 °C; 4,087 °F),[3] an oxyhydrogen flame burns at 3,073 K (2,800 °C; 5,072 °F) and an acetylene/oxygen flame burns at about 3,773 K (3,500 °C; 6,332 °F).[4]

During the early 20th century, before the development and availability of coated arc welding electrodes in the late 1920s that were capable of making sound welds in steel, oxy-acetylene welding was the only process capable of making welds of exceptionally high quality in virtually all metals in commercial use at the time. These included not only carbon steel but also alloy steels, cast iron, aluminium, and magnesium. In recent decades it has been superseded in almost all industrial uses by various arc welding methods offering greater speed and, in the case of gas tungsten arc welding, the capability of welding very reactive metals such as titanium.

Oxy-acetylene welding is still used for metal-based artwork and in smaller home-based shops, as well as situations where accessing electricity (e.g., via an extension cord or portable generator) would present difficulties. The oxy-acetylene (and other oxy-fuel gas mixtures) welding torch remains a mainstay heat source for manual brazing, as well as metal forming, preparation, and localized heat treating. In addition, oxy-fuel cutting is still widely used, both in heavy industry and light industrial and repair operations.

In oxy-fuel welding, a welding torch is used to weld metals. Welding metal results when two pieces are heated to a temperature that produces a shared pool of molten metal. The molten pool is generally supplied with additional metal called filler. Filler material selection depends upon the metals to be welded.

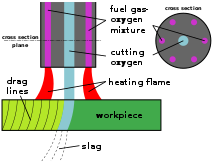

In oxy-fuel cutting, a torch is used to heat metal to its kindling temperature. A stream of oxygen is then trained on the metal, burning it into a metal oxide that flows out of the kerf as dross.[5]

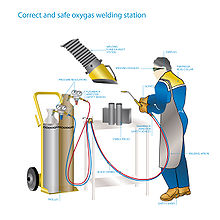

Torches that do not mix fuel with oxygen (combining, instead, atmospheric air) are not considered oxy-fuel torches and can typically be identified by a single tank (oxy-fuel cutting requires two isolated supplies, fuel and oxygen). Most metals cannot be melted with a single-tank torch. Consequently, single-tank torches are typically suitable for soldering and brazing but not for welding.

- ^ Carlisle, Rodney (2004). Scientific American Inventions and Discoveries, p.365. John Wright & Songs, Inc., New Jersey. ISBN 0-471-24410-4.

- ^ Lide, David R. (2004-06-29). CRC Handbook of Chemistry and Physics, 85th Edition. CRC Press. pp. 15–52. ISBN 9780849304859.

- ^ "Adiabatic Flame Temperature". www.engineeringtoolbox.com. Retrieved 2015-07-02.

- ^ Basic Mech Engg,3E Tnc Syllb. Tata McGraw-Hill Education. 2000-05-01. p. 106. ISBN 9780074636626.

- ^ The Oxy-Acetylene Handbook, Union Carbide Corp 1975