| Part of a series of articles on |

| Nanomaterials |

|---|

|

| Carbon nanotubes |

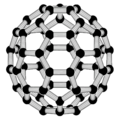

| Fullerenes |

| Other nanoparticles |

| Nanostructured materials |

Carbon nanotubes (CNTs) are cylinders of one or more layers of graphene (lattice). Diameters of single-walled carbon nanotubes (SWNTs) and multi-walled carbon nanotubes (MWNTs) are typically 0.8 to 2 nm and 5 to 20 nm, respectively, although MWNT diameters can exceed 100 nm. CNT lengths range from less than 100 nm to 0.5 m.[1]

Individual CNT walls can be metallic or semiconducting depending on the orientation of the lattice with respect to the tube axis, which is called chirality. MWNT's cross-sectional area offers an elastic modulus approaching 1 TPa and a tensile strength of 100 GPa, over 10-fold higher than any industrial fiber. MWNTs are typically metallic and can carry currents of up to 109 A cm−2. SWNTs can display thermal conductivity of 3500 W m−1 K−1, exceeding that of diamond.[2]

As of 2013[update], carbon nanotube production exceeded several thousand tons per year, used for applications in energy storage, device modelling, automotive parts, boat hulls, sporting goods, water filters, thin-film electronics, coatings, actuators and electromagnetic shields. CNT-related publications more than tripled in the prior decade, while rates of patent issuance also increased.[2] Most output was of unorganized architecture. Organized CNT architectures such as "forests", yarns and regular sheets were produced in much smaller volumes.[2] CNTs have even been proposed as the tether for a purported space elevator.[3][4]

Recently, several studies have highlighted the prospect of using carbon nanotubes as building blocks to fabricate three-dimensional macroscopic (>1 mm in all three dimensions) all-carbon devices. Lalwani et al. have reported a novel radical initiated thermal crosslinking method to fabricated macroscopic, free-standing, porous, all-carbon scaffolds using single- and multi-walled carbon nanotubes as building blocks.[5] These scaffolds possess macro-, micro-, and nano- structured pores and the porosity can be tailored for specific applications. These 3D all-carbon scaffolds/architectures may be used for the fabrication of the next generation of energy storage, supercapacitors, field emission transistors, high-performance catalysis, photovoltaics, and biomedical devices and implants.

- ^ Zhang, R.; Zhang, Y.; Zhang, Q.; Xie, H.; Qian, W.; Wei, F. (2013). "Growth of Half-Meter Long Carbon Nanotubes Based on Schulz–Flory Distribution". ACS Nano. 7 (7): 6156–61. doi:10.1021/nn401995z. PMID 23806050.

- ^ a b c De Volder, M. F. L.; Tawfick, S. H.; Baughman, R. H.; Hart, A. J. (2013). "Carbon Nanotubes: Present and Future Commercial Applications". Science. 339 (6119): 535–539. Bibcode:2013Sci...339..535D. CiteSeerX 10.1.1.703.4188. doi:10.1126/science.1222453. PMID 23372006. S2CID 37239907.

- ^ Edwards, Brad C. (2003). The Space Elevator. BC Edwards. ISBN 978-0-9746517-1-2.

- ^ Collins, P.G. (2000). "Nanotubes for Electronics" (PDF). Scientific American. 283 (6): 67–69. Bibcode:2000SciAm.283f..62C. doi:10.1038/scientificamerican1200-62. PMID 11103460. Archived from the original (PDF) on 2008-06-27.

Zhang, M.; Fang, S; Zakhidov, AA; Lee, SB; Aliev, AE; Williams, CD; Atkinson, KR; Baughman, RH (2005). "Strong, Transparent, Multifunctional, Carbon Nanotube Sheets". Science. 309 (5738): 1215–1219. Bibcode:2005Sci...309.1215Z. doi:10.1126/science.1115311. PMID 16109875. S2CID 36429963. - ^ a b Lalwani, Gaurav; Kwaczala, Andrea Trinward; Kanakia, Shruti; Patel, Sunny C.; Judex, Stefan; Sitharaman, Balaji (2013). "Fabrication and characterization of three-dimensional macroscopic all-carbon scaffolds". Carbon. 53: 90–100. doi:10.1016/j.carbon.2012.10.035. PMC 3578711. PMID 23436939.