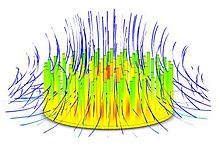

All electronic devices and circuitry generate excess heat and thus require thermal management to improve reliability and prevent premature failure. The amount of heat output is equal to the power input, if there are no other energy interactions.[1] There are several techniques for cooling including various styles of heat sinks, thermoelectric coolers, forced air systems and fans, heat pipes, and others. In cases of extreme low environmental temperatures, it may actually be necessary to heat the electronic components to achieve satisfactory operation.[2]

- ^ Cengel, Yunus; Ghajar, Afshin (2015). Heat and Mass Transfer: Fundamentals and Applications (PDF). McGraw Hill. pp. Chapter 15. ISBN 978-0073398181.

- ^ "OSHA Technical Manual (OTM) - Section III: Chapter 4 - Heat Stress - Occupational Safety and Health Administration". www.osha.gov.