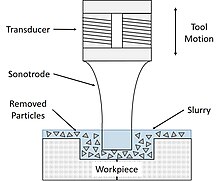

Ultrasonic machining is a subtractive manufacturing process that removes material from the surface of a part through high frequency, low amplitude vibrations of a tool against the material surface in the presence of fine abrasive particles. The tool travels vertically or orthogonal to the surface of the part at amplitudes of 0.05 to 0.125 mm (0.002 to 0.005 in.).[1] The fine abrasive grains are mixed with water to form a slurry that is distributed across the part and the tip of the tool. Typical grain sizes of the abrasive material range from 100 to 1000, where smaller grains (higher grain number) produce smoother surface finishes.[1]

Ultrasonic vibration machining [2] is typically used on brittle materials as well as materials with a high hardness due to the microcracking mechanics.

- ^ a b Kalpakjian, Serope (2008). Manufacturing Processes for Engineering Materials. Upper Saddle River, NJ: Pearson Education, Inc. pp. 552–553. ISBN 978-0-13-227271-1.

- ^ Blogger, M. "Best ultrasonic Flow Detector Price sensors, arduino, Operations Various models and Effects". INDIA SEARCH ONLINE. Retrieved 2020-08-30.